PRODUCTS DETAILS

Fully Insulated (FIW) & Zero-Defect

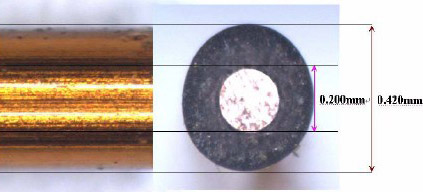

Fully Insulated (FIW) & Zero-Defect Enameled Round Copper Wire

Fully insulated (FIW) enameled round copper wire, has solderability, zero-defect, high temperature resistance, and insulation reinforced. It can meet the standard of IEC60317-56 (2012.05) / IEC60950 U clause. The high voltage resistance provides the requests of miniaturized design for electronic products with better winding and lower cost. It widely used to small transformers, switch power supply. Especially it is the best new material to replace triple insulated wire(TIW). Our FIW wire has certified by VDE.

Main Characteristics

1. Thermal class: 180 degrees (triple insulated wire only at 105~130 degrees)

2. High breakdown voltage: >15KV

3. High insulation strength: 6000Vrms/1min

4. Solderability at 390℃/2sec (no need to peel off the film)

5. High anti-softening temperature at 250℃, no cut-through in 2 minutes, no film cracking after Air Reflow (peak temperature at 260℃)

6. Color option: nature(N)/red(R)/green(G)/blue(B)/violet(V)/brown(BR)/yellow(Y)

7. Excellent winding performance, suitable for high-speed automatic winding machine

8. Minimum diameter at 0.040mm

9. At same specification, FIW has lower cost than triple insulated wire(TIW)

Main Technical Parameters

Diameter | Tolerance | Resistance (Ω, 20℃) | Outer Diameter (mm) | ||||||

(mm) | (mm) | Min | Max | FIW6 | FIW8 | FIW10 | |||

min | max | min | max | min | max | ||||

0.040 | ±0.002 | 12.23 | 15.20 | 0.080 | 0.089 | 0.100 | 0.109 | - | - |

0.050 | ±0.002 | 7.981 | 9.528 | 0.095 | 0.105 | 0.117 | 0.127 | ||

0.060 | ±0.002 | 5.614 | 6.526 | 0.113 | 0.125 | 0.139 | 0.151 | - | - |

0.070 | ±0.003 | 4.050 | 4.890 | 0.123 | 0.135 | 0.149 | 0.161 | 0.175 | 0.187 |

0.080 | ±0.003 | 3.133 | 3.703 | 0.137 | 0.150 | 0.165 | 0.178 | 0.193 | 0.206 |

0.090 | ±0.003 | 2.495 | 2.900 | 0.149 | 0.162 | 0.177 | 0.190 | 0.205 | 0.218 |

0.100 | ±0.003 | 2.034 | 2.333 | 0.165 | 0.180 | 0.197 | 0.212 | 0.229 | 0.244 |

0.120 | ±0.003 | 1.426 | 1.604 | 0.195 | 0.212 | 0.231 | 0.248 | 0.267 | 0.284 |

0.160 | ±0.003 | 0.8122 | 0.8906 | 0.250 | 0.271 | 0.294 | 0.315 | 0.338 | 0.359 |

0.180 | ±0.003 | 0.6444 | 0.7007 | 0.278 | 0.301 | 0.326 | 0.349 | 0.374 | 0.397 |

0.200 | ±0.003 | 0.5237 | 0.5657 | 0.303 | 0.327 | 0.353 | 0.377 | 0.403 | 0.427 |

0.250 | ±0.004 | 0.3345 | 0.3628 | 0.373 | 0.402 | 0.433 | 0.462 | 0.493 | 0.522 |

0.300 | ±0.004 | 0.2335 | 0.2506 | 0.432 | 0.462 | 0.494 | 0.524 | - | - |

0.350 | ±0.004 | 0.1722 | 0.1834 | 0.486 | 0.516 | 0.548 | 0.578 | - | - |

0.400 | ±0.005 | 0.1316 | 0.1407 | 0.541 | 0.571 | 0.603 | 0.633 | - | - |

Weight per Kilometer (kg/km) and Length per Kilogram (km/kg) of FIW Wire

Diameter | Weight per kilometer of FIW wire (KG/KM) | Length per kilogram of FIW wire (KM/KG) | ||||||||

(mm) | FIW6 | FIW7 | FIW8 | FIW9 | FIW10 | FIW6 | FIW7 | FIW8 | FIW9 | FIW10 |

0.070 | 0.046 | 0.048 | 0.053 | 0.057 | 0.061 | 21.80 | 20.80 | 19.00 | 17.50 | 16.50 |

0.080 | 0.057 | 0.063 | 0.066 | 0.071 | 0.077 | 17.40 | 16.00 | 15.00 | 14.00 | 13.00 |

0.090 | 0.071 | 0.077 | 0.081 | 0.086 | 0.091 | 14.20 | 13.00 | 12.40 | 11.70 | 11.00 |

0.100 | 0.089 | 0.094 | 0.101 | 0.107 | 0.113 | 11.30 | 10.60 | 9.90 | 9.40 | 8.80 |

0.120 | 0.127 | 0.133 | 0.142 | 0.151 | 0.160 | 7.90 | 7.50 | 7.00 | 6.60 | 6.30 |

0.160 | 0.22 | 0.232 | 0.244 | 0.257 | 0.271 | 4.56 | 4.31 | 4.10 | 3.90 | 3.70 |

0.200 | 0.337 | 0.353 | 0.370 | 0.388 | 0.405 | 2.97 | 2.84 | 2.71 | 2.58 | 2.48 |

0.250 | 0.524 | 0.547 | 0.572 | 0.599 | 0.627 | 1.91 | 1.83 | 1.75 | 1.67 | 1.60 |

0.300 | 0.738 | 0.763 | 0.794 | 0.824 | - | 1.36 | 1.31 | 1.26 | 1.22 | - |

0.350 | 0.980 | 1.020 | 1.047 | 1.086 | - | 1.02 | 0.98 | 0.96 | 0.92 | - |

0.400 | 1.268 | 1.301 | 1.336 | - | - | 0.79 | 0.77 | 0.75 | - | - |

0.450 | 1.581 | 1.617 | 1.655 | - | - | 0.64 | 0.62 | 0.61 | - | - |

0.500 | 1.968 | 2.023 | - | - | - | 0.51 | 0.50 | - | - | |